Compact car body work has evolved from boxy practicality to sleek aesthetics, driven by materials science advances. Lightweight aluminum and advanced steel alloys enable curvier designs, better fuel efficiency, and enhanced safety. This transformation influences collision repairs, benefits consumers with simpler, faster fixes, and pushes the industry towards more efficient vehicles.

The evolution of compact car body work has drastically transformed the auto industry. Once characterized by bulky designs and heavy materials, modern compact cars boast sleek aesthetics and lightweight components. This metamorphosis isn’t just cosmetic; it’s a game-changer in terms of efficiency and performance. From innovative design techniques to cutting-edge materials, these changes have not only enhanced fuel economy but also revolutionized the driving experience. Let’s explore how compact car body work has reshaped both the industry and consumer expectations.

- Evolution of Design: From Bulky to Sleek

- Lightweight Materials: A Game Changer

- Impact on Efficiency and Performance

Evolution of Design: From Bulky to Sleek

The evolution of compact car body work has been a fascinating journey from bulky, boxy designs to sleek, aerodynamic shapes. In the early days, cars were designed with practicality in mind, prioritizing space and functionality over aesthetics. These vehicles often featured robust, sturdy bodies that could withstand rough handling and everyday wear and tear. However, as the automotive industry began to embrace style and sophistication, the focus shifted towards creating more aesthetically pleasing designs without compromising on safety and durability.

This change was driven by several factors, including advancements in materials science and manufacturing techniques. The introduction of lightweight materials like aluminum and advanced steel alloys allowed for more streamlined designs while ensuring structural integrity. Car makers started to experiment with new body styles, such as curved lines and tapered edges, which not only looked modern but also improved fuel efficiency and reduced drag. As a result, compact cars became not just practical choices, but also iconic symbols of style and innovation, setting the stage for future auto industry trends and paving the way for safer and more efficient collision repair processes in dedicated centers, including hail damage repair and car damage repair services.

Lightweight Materials: A Game Changer

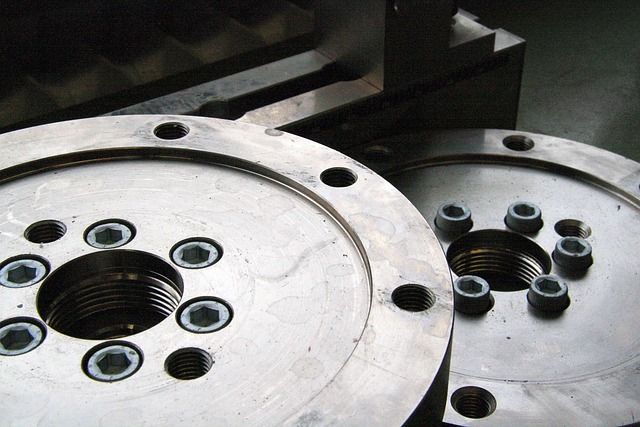

The shift towards using lightweight materials in compact car body work has been a game-changer for the auto industry. Traditional steel bodies, once the standard, have been gradually replaced by advanced alternatives like aluminum and high-strength steels. This change isn’t just about aesthetics; it’s driven by the need to improve fuel efficiency and enhance safety features. By reducing vehicle weight, these materials enable compact cars to achieve better gas mileage without compromising on structural integrity.

This innovation has had a ripple effect across the industry. Not only has it forced manufacturers to re-evaluate their design processes, but it’s also impacted areas like car damage repair and autobody repairs. Bumper repair, for instance, has become more precise and efficient due to the easier workability of these lightweight materials. This shift not only benefits consumers with more fuel-efficient vehicles but also promises a simpler and faster process for any necessary repairs.

Impact on Efficiency and Performance

The evolution of compact car body work has significantly influenced the auto industry’s overall efficiency and performance dynamics. By optimizing the design and construction of smaller vehicles, manufacturers have achieved remarkable weight reduction, a key factor in enhancing fuel efficiency. Lightweight materials and innovative manufacturing techniques, such as advanced stamping processes, allow for more streamlined bodies, improving aerodynamics and reducing drag—a critical aspect in achieving better gas mileage.

Furthermore, this trend has paved the way for improved performance capabilities. Compact cars, with their agile handling and responsive engines, offer drivers a thrilling driving experience while also contributing to reduced carbon emissions. The integration of advanced safety features, made possible by more precise dent removal and fleet repair services, further elevates these vehicles’ overall performance, ensuring passengers’ safety without compromising on size or efficiency.

Compact car body work has evolved dramatically, transforming the auto industry with sleek designs and lightweight materials. This shift has significantly improved efficiency and performance, setting new standards for modern vehicles. As we continue to advance, further innovations in compact car body work will undoubtedly shape the future of transportation, offering drivers improved experiences while minimizing environmental impact.