Compact car body work involves a balance between aesthetics and safety, using durable materials like aluminum and AHSS for lightweight yet robust frames. Advanced coatings protect against corrosion, while laser welding and robotic spot welding ensure precise assembly. CAD software and digital measurement systems enhance accuracy, meeting industry standards for superior customer satisfaction and vehicle longevity.

In the competitive automotive market, compact car body work is a delicate art that combines aesthetics and functionality. This article explores the key elements driving success in designing and manufacturing compact car bodies. From understanding the intricate structure of these vehicles to selecting materials for enhanced durability and lightweight construction, we delve into advanced assembly techniques ensuring seamless integration. Discover how these strategies contribute to creating efficient, reliable, and visually appealing compact cars that meet modern demands.

- Understanding Compact Car Body Structure

- Choosing Materials for Durability and Weight Efficiency

- Advanced Techniques for Seamless Assembly

Understanding Compact Car Body Structure

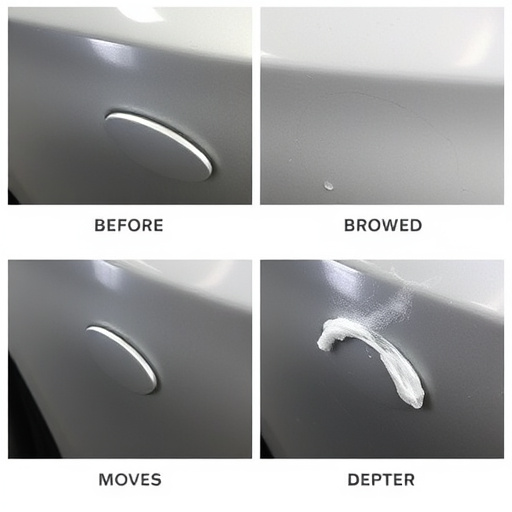

The structure of a compact car body is meticulously designed to balance aesthetics and functionality. It consists of several key components that work harmoniously to provide both safety and style. Understanding this structure is paramount in achieving excellence in compact car body work. The exterior panels, such as the fenders, doors, and hood, are crucial elements that protect the vehicle’s framework while contributing to its overall look. These panels are crafted from durable materials like steel or advanced composites, ensuring they can withstand impacts during a collision or fender bender, preserving the car’s structural integrity.

Furthermore, the frame acts as the backbone of the vehicle, providing rigidity and support for all other components. In compact cars, the frame is often designed to be lightweight yet robust, incorporating specialized alloys or high-strength steel to enhance fuel efficiency without compromising safety. Skilled technicians must master the art of aligning and repairing these intricate structures when addressing car scratch repair or collision repair services, ensuring the vehicle not only looks its best but also maintains optimal performance and safety standards.

Choosing Materials for Durability and Weight Efficiency

When it comes to compact car body work, selecting the right materials is paramount for both durability and weight efficiency. Lightweight yet robust options like aluminum and advanced high-strength steels (AHSS) are gaining popularity in the automotive industry due to their superior strength-to-weight ratios. These materials not only reduce the overall vehicle weight, enhancing fuel efficiency and handling but also withstand impact better during a fender bender or collision, ensuring the safety of passengers.

Furthermore, modern coatings and finishing techniques play a crucial role in protecting these materials from corrosion and environmental factors. Polyurethane paint systems, for instance, offer excellent durability and chip resistance, while underbody coatings provide an extra barrier against road salt and other contaminants. Choosing the right materials and finishes ensures that compact car body work not only looks appealing but also stands the test of time, making it easier to find reliable automotive repair services if ever needed.

Advanced Techniques for Seamless Assembly

In the realm of compact car body work, seamless assembly is paramount to achieving superior quality and aesthetics. Advanced techniques such as laser welding and precision robotic spot welding have transformed the industry. These methods ensure precise, strong, and virtually invisible joints, setting a new standard for craftsmanship. Laser welding, in particular, offers unparalleled accuracy, allowing for intricate designs while minimizing heat input, which can cause material distortion or discoloration.

Additionally, the integration of computer-aided design (CAD) software and digital measurement systems has revolutionized collision repair centers and vehicle restoration shops. These technologies enable exact measurements and precise cuts, resulting in perfect panel alignment. By combining advanced assembly techniques with cutting-edge technology, auto collision centers can deliver top-notch compact car body work that not only meets but exceeds industry standards, ensuring customer satisfaction and vehicle longevity.

Compact car body work combines structural integrity, weight optimization, and aesthetic appeal to create a seamless driving experience. By understanding the unique demands of compact vehicles, choosing durable yet lightweight materials, and employing advanced assembly techniques, manufacturers can deliver efficient, reliable, and visually pleasing cars that meet modern consumer expectations. These key elements ensure not just a successful build but also a satisfying journey for every driver.