The evolution of compact car body work has seen a remarkable journey from functional basics to innovative design, driven by technological advancements in lightweight materials and manufacturing processes. Early models focused on efficiency with simple, boxy shapes, but consumer preferences shifted towards fluidic lines, curved surfaces, and aerodynamic profiles, transforming compact cars into sleek, sophisticated machines. Today, modern compact cars balance stylish design, superior build quality, and outstanding safety features, setting new benchmarks for both car enthusiasts and eco-conscious consumers. This revolution has been facilitated by advanced materials like high-strength steels, aluminum alloys, and composites, as well as techniques such as precision casting, 3D printing, and CAD, resulting in improved structural integrity, fuel efficiency, and performance while promoting sustainability.

“The auto industry has seen a quiet revolution thanks to compact car body work, transforming not just aesthetics but also functionality and sustainability. This evolution, driven by innovative design and advanced materials, has reshaped the way vehicles are built and perceived. From lightweight alloys to sophisticated computer-aided designs, compact cars now offer enhanced performance, improved fuel efficiency, and reduced environmental impact. Explore how these changes have set a new standard across the industry.”

- Evolution of Compact Car Design: From Basics to Innovation

- Technical Advancements in Lightweight Materials and Manufacturing

- Impact on Sustainability and Performance: A New Standard Set

Evolution of Compact Car Design: From Basics to Innovation

The evolution of compact car design has been a fascinating journey from functional basics to innovative aesthetics. In the early days, compact cars were primarily focused on efficiency and practicality, with simple, boxy designs that optimized space and reduced weight. These initial models set the stage for future compact car body work, emphasizing minimalism and functionality. Over time, as consumer preferences shifted towards more stylish and desirable vehicles, car manufacturers began to experiment with fluidic lines, curved surfaces, and aerodynamic profiles, transforming the compact car into a sleek and sophisticated machine.

This shift in design philosophy not only improved the aesthetic appeal of compact cars but also influenced the overall direction of the auto industry. Manufacturers started investing heavily in advanced materials, precision engineering, and cutting-edge technologies to create lightweight yet sturdy body structures, further enhancing fuel efficiency and performance. As a result, today’s compact cars offer a perfect balance between stylish design, superior build quality, and outstanding safety features, setting new standards for both car enthusiasts and eco-conscious consumers alike. This evolution in compact car body work has indeed revolutionized the way we perceive and interact with small vehicles, making them not just practical choices but also expressions of modern aesthetics and technological prowess.

Technical Advancements in Lightweight Materials and Manufacturing

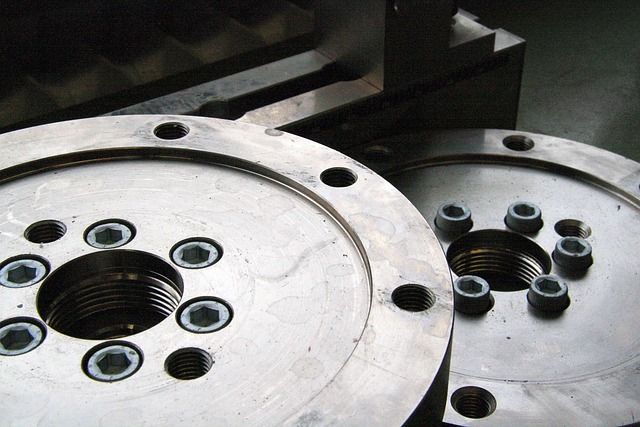

The evolution of compact car body work is deeply intertwined with remarkable technical advancements in lightweight materials and manufacturing processes. Automakers have successfully replaced heavy metal components with innovative alternatives such as high-strength steels, aluminum alloys, and even advanced composite materials. These materials not only reduce vehicle weight but also offer superior crashworthiness and improved fuel efficiency.

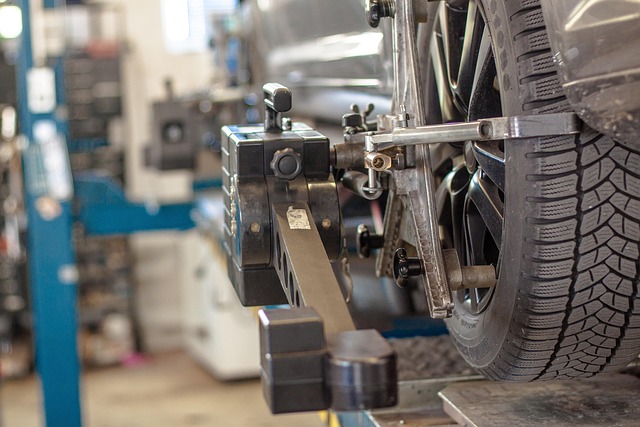

Advanced manufacturing techniques like precision casting, 3D printing, and computer-aided design (CAD) have further revolutionized compact car body work. These technologies enable more intricate designs, precise dimensions, and faster production times. As a result, modern compact cars boast sleek aesthetics, enhanced structural integrity, and greater repairability, exemplified in efficient fender repair and high-quality body shop services. This shift towards lightweight materials and sophisticated manufacturing has set new standards for the automotive industry, paving the way for more sustainable and technologically advanced vehicles.

Impact on Sustainability and Performance: A New Standard Set

The shift towards compact car body work has significantly reshaped the automotive industry’s focus on sustainability and performance. As manufacturers embraced lighter materials like aluminum and advanced engineering techniques, vehicles became more fuel-efficient and environmentally friendly. This transition marked a departure from the traditional steel-heavy bodies, leading to reduced weight, lower emissions, and improved overall sustainability.

This new standard set by compact car body work has not only contributed to eco-conscious consumer choices but also pushed the boundaries of performance. Lighter cars can achieve higher fuel economy without compromising on power, offering drivers a more efficient and enjoyable driving experience. Moreover, advanced body repair techniques in car body shops have become crucial in maintaining these precision-engineered structures, ensuring that even in the event of a dent or damage, the structural integrity remains intact, further enhancing safety and performance.

Compact car body work has undergone a remarkable evolution, driven by technical advancements in materials and manufacturing. This transformation has not only redefined aesthetics but also significantly impacted sustainability and performance across the auto industry. By utilizing lightweight materials and innovative design principles, modern compact cars set a new standard, offering efficient, eco-friendly, and high-performing vehicles that cater to diverse consumer needs. This shift marks a pivotal moment in automotive history, paving the way for further breakthroughs in green technology and design.