The evolution of compact car body work reflects the auto industry's continuous pursuit of innovation and efficiency. From functional designs in the early 20th century to sleek aesthetics driven by rising fuel costs and urban growth, compact cars have undergone significant transformations. The 1970s introduced modern space-saving designs, lightweight materials, and streamlined profiles, while technological advancements over time have led to safer, ergonomically designed models with enhanced comfort features without sacrificing size or efficiency. These changes have significantly impacted design trends, production techniques, and consumer expectations in the automotive industry, emphasizing lightweight materials like high-strength steel, aluminum, and CFRP, as well as advanced manufacturing processes such as CNC machining, laser welding, and robotic assembly. This evolution has contributed to improved fuel efficiency, reduced environmental impact, enhanced safety, and market accessibility, setting the trend for the future of compact car body work and the auto industry at large.

“The auto industry has undergone a quiet revolution through the evolution of compact car body work. This article explores how advancements in design and manufacturing have reshaped the market. From historical perspectives, we trace the transition to lighter materials and innovative production techniques that drive fuel efficiency and safety. These changes not only make compact cars more accessible but also set new standards for the industry. Discover how these developments have left an indelible mark on modern automotive landscape.”

- The Evolution of Compact Car Design: A Historical Perspective

- Technical Innovations in Light-Weight Materials and Manufacturing

- Impact on Fuel Efficiency, Safety, and Accessibility in the Auto Market

The Evolution of Compact Car Design: A Historical Perspective

The evolution of compact car design is a testament to the auto industry’s constant pursuit of innovation and efficiency. In the early 20th century, vehicles were primarily focused on utility and practicality, with designs that emphasized functionality over style. However, as the automotive landscape began to transform, manufacturers started to experiment with sleek and sophisticated aesthetics, paving the way for compact cars to become a dominant force in the market. This shift can be attributed to several factors, including rising fuel costs, growing urban populations, and a changing consumer preference for smaller, more manageable vehicles.

The 1970s marked a significant turning point with the introduction of the first modern compact cars, featuring innovative body work that optimizes space and performance. These designs incorporated lightweight materials, streamlined profiles, and clever engineering to create vehicles that were not only economical but also aesthetically appealing. Over time, as technology advanced, auto manufacturers refined their compact car body work, incorporating sophisticated safety features, improved ergonomics, and enhanced comfort without compromising on size or efficiency. This historical transformation showcases how compact car body work has revolutionized the automotive industry, influencing design trends, production techniques, and consumer expectations alike.

Technical Innovations in Light-Weight Materials and Manufacturing

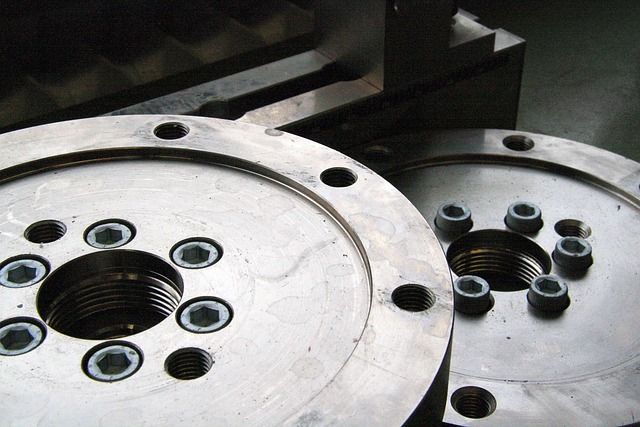

The evolution of compact car body work brought about significant technical innovations in light-weight materials and manufacturing processes. Auto manufacturers began to explore alternative materials such as high-strength steel, aluminum, and advanced composites like carbon fiber reinforced polymer (CFRP). These materials offered substantial weight reduction compared to traditional steels, enabling the creation of lighter yet robust vehicle structures.

Advanced manufacturing techniques, including computer numerical control (CNC) machining, laser welding, and robotic assembly, further streamlined production processes. These technologies facilitated precise cutting, joining, and shaping of light-weight materials, resulting in more efficient and cost-effective compact car body work. As a result, vehicles became not only lighter but also stronger, leading to improved fuel efficiency, enhanced handling dynamics, and reduced environmental impact—a trend that continues to shape the future of the auto industry.

Impact on Fuel Efficiency, Safety, and Accessibility in the Auto Market

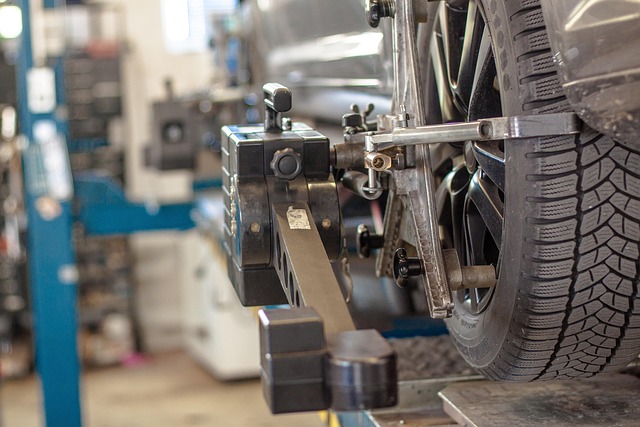

The introduction of compact car body work brought about significant changes in the automotive industry, impacting several key areas. One of the most notable effects was an improvement in fuel efficiency. Smaller, more streamlined designs reduced overall vehicle weight, allowing for enhanced fuel economy and lower emissions. This shift was particularly evident as auto manufacturers prioritized eco-friendly options to meet rising environmental standards.

Additionally, compact car body work contributed to enhanced safety features. The focus on lightweight materials and efficient structures allowed engineers to redistribute weight, improving a vehicle’s handling and stability. This led to better collision performance in tests conducted at collision centers and auto body shops, ultimately making compact cars safer for drivers on the road. Moreover, the accessibility of these vehicles in the market expanded, offering consumers more options for cost-effective, efficient, and safe transportation.

Compact car body work has undergone a remarkable transformation, revolutionizing the automotive industry. The historical evolution of design, coupled with technical innovations in lightweight materials and manufacturing, has significantly impacted fuel efficiency, safety, and accessibility. These changes not only cater to modern consumer demands but also set a new standard for environmental sustainability and affordable motoring. As the industry continues to navigate future challenges, the principles of compact car body work will undoubtedly remain a cornerstone of automotive innovation.